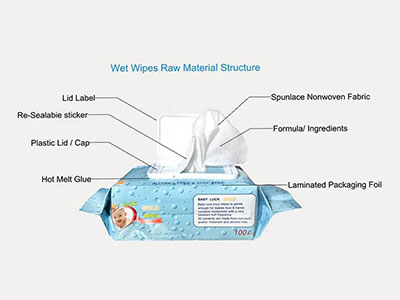

Wet Wipes Raw Material

The use of wet wipes is increasing as a convenient and hygienic way to clean and refresh. As a result, the demand for wet wipes raw material has also risen significantly. Wet wipe raw materials are essential for producing high quality wipes that meet consumer expectations. It is important to understand the different types of materials used in the production of wet wipes, their properties and how they affect performance.

Substrates

The substrate is the material in which your wipes will be made of. Choose from our various options to perfectly hold your ingredients.

Cotton: We are known for our 100% cotton wipes. They are kind to the skin and soft to the touch. They are water-absorbing while having water-retaining properties.

Viscose: Viscose naturally has great absorbency and strength properties and are known for their softness. They tend to be used in applications where they prevent irritation to the skin.

Polyester: Plastic fibers made through extruding molten polymer through small holes. They are widely used in wipes as they are known for having good strength.

Wood Pulp: This the main raw material used for wet wipes. They have a high surface area and a flat ribbon-like morphology which gives them good cleaning and absorbency properties.

Formulations

We offer a wide range of exclusively patented formulations for you to choose from! We provide wet wipe ingredients and raw materials that can accommodate your wipe needs.

We have a library of hundreds of formulas to choose from for your wipes. Each of our formulations are tested and proven through laboratories and agencies. We want to make sure each wipe is safe and effective for every use.

Have a formulation in mind or want to use one of our own?

Environmental protection and sustainability of wet wipes raw material

Selection of raw materials: Wet wipes are usually composed of cellulose materials, water and some additives. In order to improve the environmental protection and sustainability of wet wipes, manufacturers can choose to use renewable, organic or natural raw materials, such as bamboo fiber, natural cotton, biodegradable materials, etc., instead of non-degradable materials such as petrochemical products or plastic fibers Material.

Energy saving and emission reduction in the production process: The production process of wet wipes also needs to consider environmental protection and sustainability. Manufacturers can adopt energy-saving technologies and green energy to reduce energy consumption and greenhouse gas emissions in the production process. In addition, they can optimize production processes and reduce emissions of wastewater, air and solid waste.

Environmental protection of packaging: In addition to raw materials and production processes, the packaging of wet wipes is also one of the important considerations for environmental protection and sustainability. Manufacturers can reduce packaging waste by using recyclable materials and simplifying packaging. In addition, they also have the option of using biodegradable materials such as starch plastic.